Experience TRU system

TruCoat is not just a normal coating, it has its own system with the best quality.

Typical Lining Construction

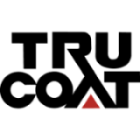

Trucoat TC 100 System on Concrete

Application Sequence

Surface Preparation: Blasting profile to sand paper Grade 2-4. All concrete surface need to be free of loose laitance, loose concrete, grease and oil. Repair blowholes, tieholes, burrholes and any form of formwork residues. For fresh concrete, please allow 28 days for the concrete to be fully cured to regain the strength.

| Layer | Primer | First coat |

|---|---|---|

| Materials | Truprime 20 | Trucoat 100 |

| Color | Cream | Buff |

| Based resin | Polyure | Aromatic Polyurea |

| Application method | Airless, Brush | Plural pump |

| Thickness (mics) | 50 -75 | 1500 |

Typical Lining Construction

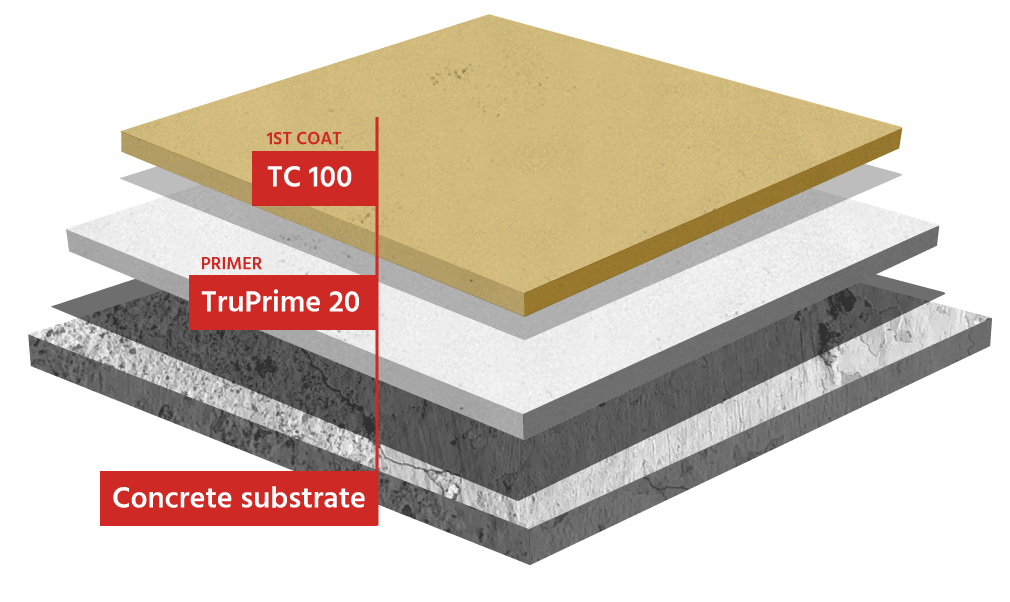

Trucoat TC 100 System on Steel

Application Sequence

Surface Preparation: Abrasive blast to SSPC- SP10 ( Sa2.5- ISO 8501-1:2007) surface cleanliness with angular surface profile height of 60-75 microns

| Layer | First coat |

|---|---|

| Materials | Trucoat 100 |

| Color | Buff |

| Based resin | Aromatic Polyurea |

| Application method | Plural pump |

| Thickness (mics) | 1500 |

Typical Lining Construction

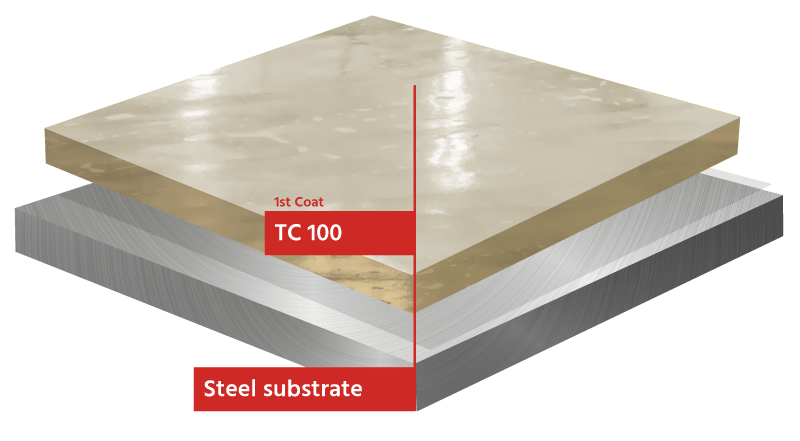

Trucoat XCR System on Concrete

Application Sequence

Surface Preparation : Blasting profile to sand paper Grade 2-4. All concrete surface need to be free of loose laitance, loose concrete, grease and oil. Repair blowholes, tieholes, burrholes and any form of formwork residues. For fresh concrete, please allow 28 days for the concrete to be fully cured to regain the strength.

| Layer | Primer | First coat | Second coat | Top coat |

|---|---|---|---|---|

| Materials | Truprime 20 | Trucoat 100 | LC 375 | XCR 125 |

| Color | Cream | Tan | Grey | Red |

| Based resin | Polyure | Aromatic Polyurea | Fluoroelastomer | Viton PTFE |

| Application method | Airless, Brush | Plural pump | Airless Spray | Airless Spray |

| Thickness (mics) | 50 -75 | 1500 | 350 | 125 |

Polyurea application

Ployurea application in various places based on different type of materials and surroundings.